Production

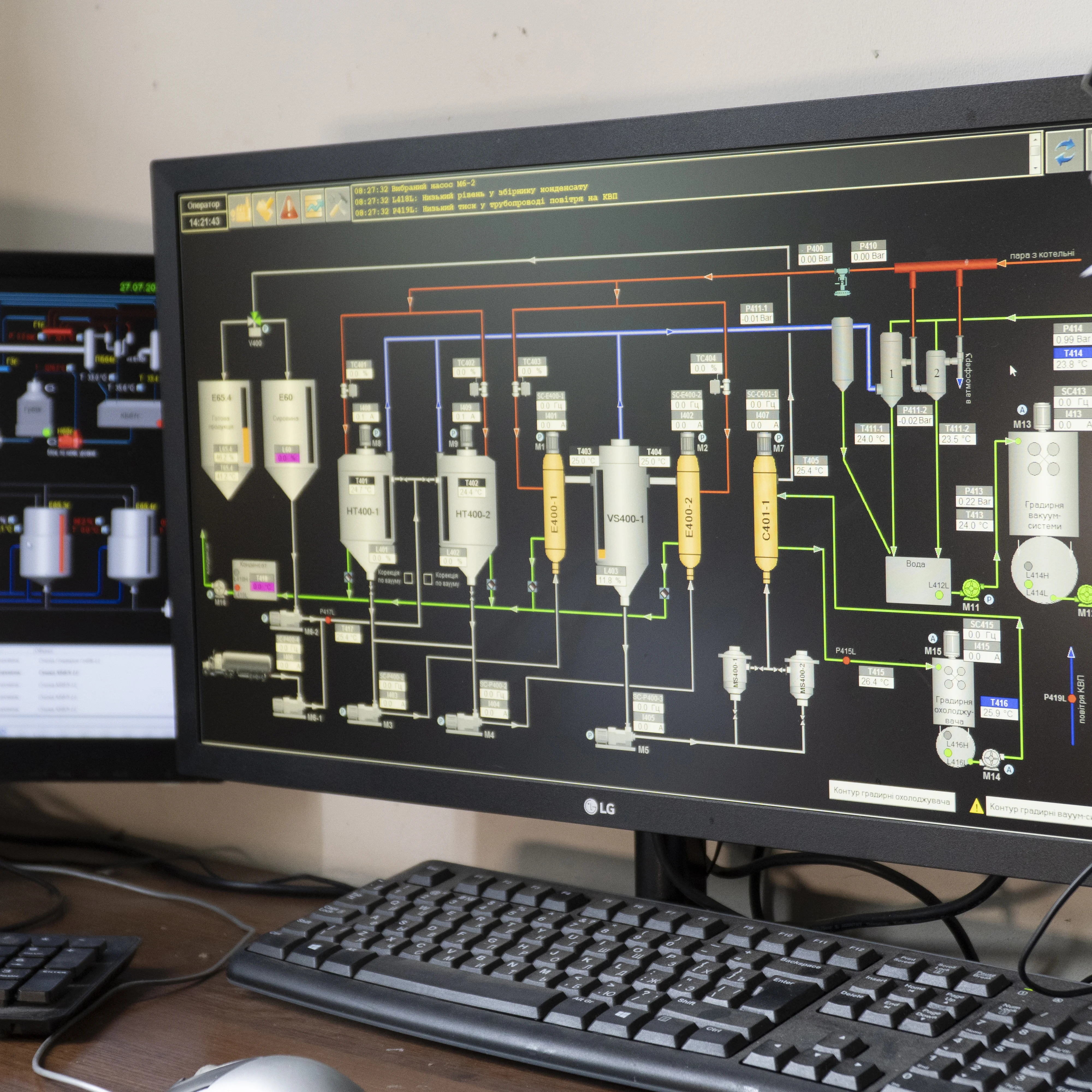

Plant Automation

Lecital production facility has implemented a flexible manufacturing automation system, which is a kind of variable automation in which many processes are intergrated by a pre-set material-handling system, and all significant segments of the lecithin production process are controlled by a central computer. While we value our employees, and their knowledge of lecithin processing, we cannot disregard the advantages of the modern computer process control systems.

Lecital’s automated process control infrastructure consists of 4 major segments: (1) measurement of important process variables such as temperature, moisture content, flow rate, vacuum pressure, ambient parameters, etc. (2) execution of an optimal process strategy derived from measured parameters, (3) automated execution of control devices such as switches, shutoff and control valves, and furnaces that make possible the process of employing the optimal strategy (4) generation of reports to facility management overviewing equipment status, production performance, and product quality.

All of the data is brought together to the operations control room, and is looked over by our experienced personnel.